INDUSTRY SECTORS WE SERVE

- Home

- / Products

- / Heating

- / Heating elements

- / Tubular heating elements for liquid

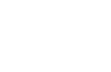

Tubular heating elements for liquids

Backer tubular heating elements represent a proven and safe technical solution for liquid heating.

The Backer tubular heating element is the most frequent alternative when it comes to exact heating of fluids. Our range of various solutions is immense and the elements are used as heating sources in many appliances, such as electric water heaters, dishwashers and washing machines, boilers, coffee machines, fryers, industrial baths and oil filled radiators.

The optimal solution for the relevant application is decided on the medium to be heated, installation of the element and power required.

Technical data

Material | Mild steel - Grade D |

Dimensions | Ø 6,5 mm |

Assembly | Inserted heating element with flange |

Connection | Direct connection for installation in equipment |

Design | One, two or three wattage ratings/elements |

Example applications

- Washing machines

- Heating pumps

- Solar heating

- Boilers

- Dish washers

- Towel heaters

- Fryers

- Industrial baths

- Disinfectors

Product examples

-

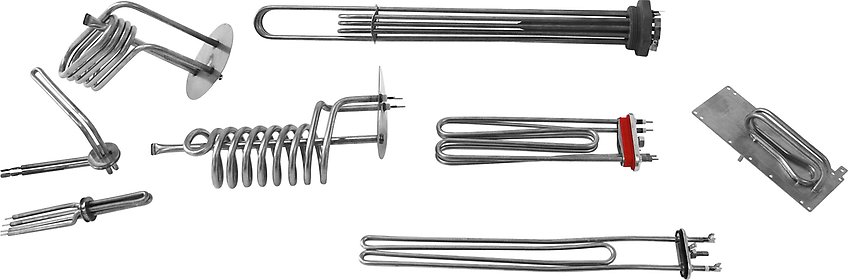

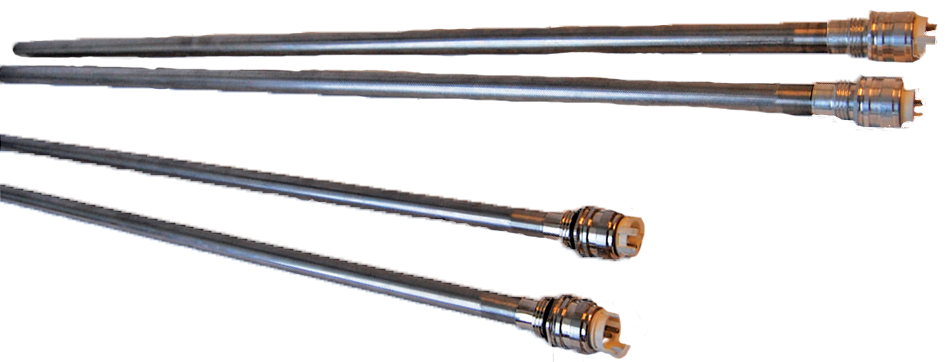

Tubular heating elements with integrated regulation for immersion heating, class II

Read more >>

-

Tubular heating elements with integrated regulation for immersion heating, class I

Tubular heating elements with integrated regulation for immersion heating, class I

Tubular heating elements with insulation class I are used in product applications where ground connection is available. They are normally produced with one-end connection and options according to cust... Read more >>

-

Tubular element with mounted thermal fuse

Tubular element with mounted thermal fuse

Most of Backer’s heating elements can be equipped with a thermal fuse. This design offers a major advantage when compared to a separately mounted thermal cut-off. Read more >>

-

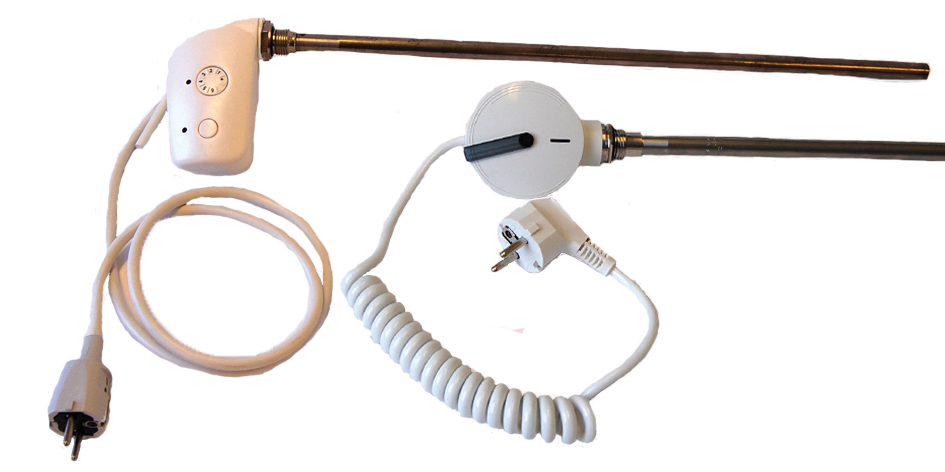

Thermostat and manually resettable thermal cut-offs

Thermostat and manually resettable thermal cut-offs

The tubular heating elements with dia. 8.5 mm can be equipped with a thermostat and a resettable thermal cut-off, mounted at the end of electrical tubular heating element. Heating elements with mounte... Read more >>

-

Screw plug immersion heater with galvanic insulated elements

Screw plug immersion heater with galvanic insulated elements

Screw plug immersion heater for direct heating of liquids. The tubular elements are galvanic isolated from the screw plug. The galvanic insulation of the tubular element reduces the risk for electrica... Read more >>

-

Immersion heater with electronic control

Immersion heater with electronic control

Immersion heater and terminal box with electronic setting of desired temperature and hysteresis with exact control via NTC. The display on the box shows current temperature and with a flashing lamp, o... Read more >>

-

Double insulated heating elements

Double insulated heating elements

We have double insulated tubular heating elements with a variety of different options for regulation and thermal protection. If preferred you can also receive help in configuring an optimal heating so... Read more >>

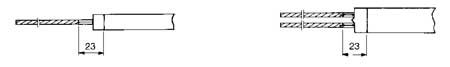

Fixing and connection devices

Savings in cost can often be made if elements are fitted with connection and fixing devices during manufacturing. Below you find the most frequent alternatives, which could be considered standard. We can also supply special flanges and alternative methods of fixing made completely to our clients' specifications.

When selecting connection and fixing devices it is often important to bear in mind the size of the series.

Types of cables and wiring

The tubular element can be eqiupped with connection that normally are spot welded on the thread. Choose from insulated or uninsulated. If uninsulated, they can be provided with insulating tubing.

Specification (most common types)

Conducting material | Insulation material | Max. operating temp. |

Copper | - | 180°C |

Copper | Silicone | 180°C |

Copper | Fibreglass/silicon | 180°C |

Nickel | - | 400°C |

Nickel | Ceramic beads | 400°C |

Nickel | Fibreglass/silicon | 200°C |

BACKER WILSON ELEMENTS PTY LTD · UNIT 3/243 SHELLHARBOUR ROAD · PORT KEMBLA, NSW 2505 · AUSTRALIA

+61 (0)2 8677 8976 · [email protected]